24 Aug Class C vs Class F Fly Ash: An Innovative Additive in Construction

Additives in construction materials such as concrete can make or break long-term cost-effectiveness. Improving the mixture of cement based construction can produce tremendous results to increase strength and reduce permeability.

What is Fly Ash?

Fly ash is a pozzolan byproduct of coal in power plants. It contains both aluminous and siliceous material that forms cement when mixed with water. When fly ash is mixed with lime and water, it creates a strong compound that is comparable to Portland cement.

ASTM C618 defines two classes of fly ash for use in concrete: Class F and Class C. ASTM C618 also delineates requirements for the physical, chemical, and mechanical properties for these two classes of fly ash. Furthermore, the ASTM C618 standard provides information on the physical, chemical, and mechanical properties of the fly ash classes.

Class C (Cementitious). Class C is derived from lignite or sub-bituminous coal. It contains a higher percentage of calcium oxide with a carbon content of less than 2 percent. This class of fly ash has self-cementing and pozzolanic properties.

Class F (Pozzolanic). Class F is derived from burning anthracite or bituminous coal. It generally contains less calcium oxide compared to Class C. This class contains less than 5 percent of carbon content, but it can also be as high as 10 percent. It contains little to no cementing properties.

Application of Fly Ash in Construction

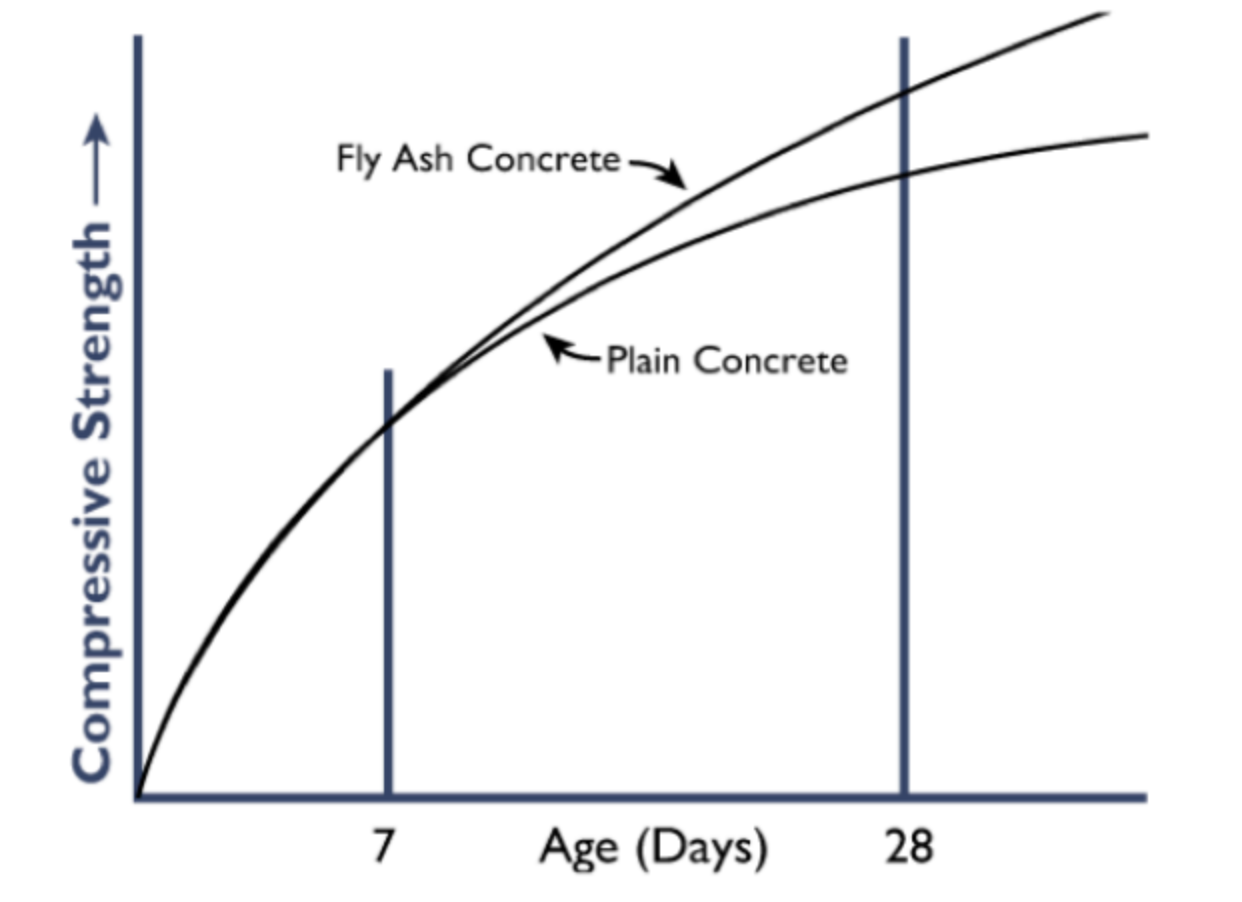

The biggest difference between Class C and Class F fly ash is their recommended dosage rate and their result on the concrete mixture. According to the US Department of Transportation, highway pavement or structural concrete mixes should use between 15 to 25 percent by weight of Class F fly ash while Class C fly ash should range from 20 to 35 percent. Class C provides concrete strength in the early stages of construction while Class F provides strength and lessens permeability in the long run. Due to its higher silica content, Class F fly ash is considered to be more effective compared to Class C fly ash.

With the addition of high-quality aggregates and fly ash in concrete mixes, cracks on a pavement and structural construction will be a thing of the past.